Imagine that you are in the middle of an important project, and suddenly your batteries run out. That’s frustrating, right? Well, here’s the good news-you can build your very own battery charger circuitry that’s intelligent, efficient, and automatic. Using an LM317 voltage regulator and a relay, this circuit not only charges your batteries but also stops charging once they’re full. Think of it as a responsible babysitter for your batteries!

This guide walks you through a simple battery charger design that can safely charge four series-connected AA cells (1.5V each). Whether your batteries are fully drained or just need a little top-up, this circuit has you covered.

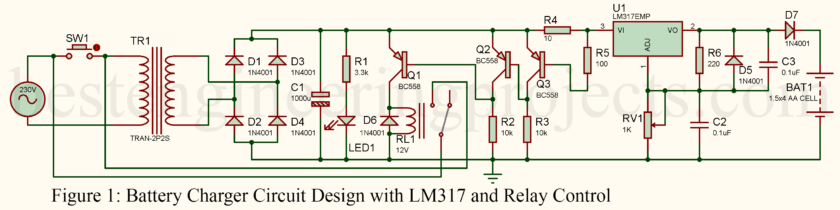

Circuit Breakdown

The circuit has three main sections:

- AC-to-DC Converter

- Relay Driver

- Charging Section

AC-to-DC Converter

This part does the heavy lifting of converting high-voltage mains AC to a safe DC voltage. Here’s how it works:

- The transformer (TR1) steps down 230V AC to 9V AC at 750mA.

- A bridge rectifier made up of diodes (D1 to D4) converts the AC into pulsating DC.

- The large capacitor C1 smoothens the DC to eliminate ripples.

- Enter the hero: the LM317 voltage regulator. This IC adjusts the output to a steady 12V DC required for charging. It’s like having a reliable coach ensuring the batteries get the exact training (voltage) they need.

- When you press switch S1, the circuit kicks into action, and LED1 lights up, signaling that the charger is alive and kicking.

Relay Driver Section

This is where the magic happens—automation! Using PNP transistors (T1, T2, T3) and a relay (RL1), this section manages when the charger starts and stops.

- Transistor Chain Reaction: The flow begins with transistor T3, which drives T2, and in turn, powers T1. It’s like a domino effect!

- When the current in the circuit exceeds 65mA, the voltage drop across resistor R4 triggers transistor T3, which sets everything in motion. The relay closes, connecting the transformer’s output to the battery.

Even after S1 is released, the relay keeps the circuit live through its normally open contacts. Smart, eh?

Charging Section

Here’s where the batteries pick up their juice. The LM317 regulator puts out a carefully adjusted voltage of 7.35V for charging. It’s fine-tuned using preset VR1 below, which in turn ensures the batteries charge at a safe voltage.

A diode (D6) between the regulator and the battery prevents overcharging by limiting the voltage to 6.7V, which is perfect for charging four AA cells. It’s like setting the perfect temperature for a cake—just enough to get it done without burning it.

Components Required

Resistors (all ¼-watt, ± 5% Carbon unless stated)

R1 = 3.3kΩ

R2, R3 = 10kΩ

R4 = 10Ω, 0.5W

R5 = 100Ω

R6 = 220Ω

VR1 = 1kΩ

Capacitor

C1 = 1000µF/25V electrolytic

C2, C3 = 0.1µF/35V electrolytic

Semiconductor

D1, D2, D3, D4, D5, D6, D7 = 1N4001

U1 = LM317

Q1, Q2, Q3 = BC558

LED1 = 5mm Red LED

Miscellaneous

TR1 = 230V AC Primary to 12V – 0V, 750mA Sec. Transformer

RL1 = 12V, 1C/O Relay

SW1 = Push to on tactile switch

Heat sink for LM317

How It All Works

Once you press S1:

- Relay RL1 latches, and the charging process begins.

- As the batteries charge, their voltage increases.

- When the voltage per cell exceeds 1.3V, the voltage drop across R4 decreases.

- Eventually, the current drops below 65mA, cutting off T3. This triggers T2 and T1 to shut down, deactivating the relay.

- The circuit disconnects the battery, and LED1 turns off, signaling that the charging is complete.

It’s an elegant dance of components, all working in harmony to protect and charge your batteries.

Why This Circuit is Perfect for You

- Automatic Shut-Off: Say goodbye to overcharging—this circuit knows when to stop.

- Customizable Voltage: You can adjust the charging voltage based on your battery’s specifications using VR1.

- Efficient and Safe: The LM317 regulator and relay ensure safe operation, protecting both your circuit and batteries.

- DIY-Friendly: With a handful of components and a basic understanding of electronics, you can build this circuit easily.

Additional Tips for Success

- Determine the Charging Voltage: For NiCd or NiMH cells, refer to the manufacturer’s specs. In this circuit, 7.35V is optimal for four 1.5V cells.

- Charging Time: Modern 700mAh cells typically need 70mA for 10 hours. Calculate the time based on your battery’s capacity.

- Fine-Tuning: After fully charging the batteries, measure the open-circuit voltage. Add 0.65V (diode drop) to set the LM317’s bias accurately.

Conclusion

Below is a very simple battery charger circuit design, using an LM317 voltage regulator with relay control. Ideal to satisfy the amateur radio enthusiast and to maintain the health of its batteries, this is simply not to be missed.

You can easily build a charger that saves you not only the hassle of batteries but also your valuable time and money-all in minimal effort. So, get rolling, get your components, and start building this DIY battery charger today!

Nice projects brother. I wonder if there is any software tool that I can use to redesign and simulate the schematic, preferably an open source.